Lihlahisoa

Thepa e phahameng ea ho kuta Homogeneous Emulsification Tank Machinery Equipment

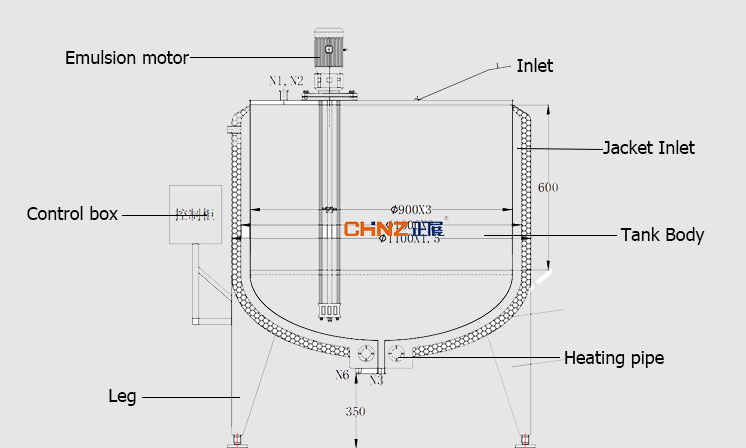

Tlhaloso

· Ts'ebetso ea ts'ebetso

Tanka ea emulsification e nang le lisebelisoa (joalo ka sekoti, sekoti le sekoti le valve joalo-joalo) ho bonolo ho sebetsa le ho e hlokomela.

·Ts'ebetso ea Bophelo bo Botle

Tanka e nang le mofuta o tloaelehileng oa lijana holimo le tlase. Linonyello tsohle le ka hare ho tanka ke seipone se felileng ntle le sekhutlo se shoeleng mme se hloekisoa habonolo(Moqapi oa bohloeki). Bokhopo bo ka holimo Ra ≤ 0,22μm.

· Ts'ebetso ea Insulation

Thepa ea insulation ke foam ea polyurethane, botenya ba PU ho fihla ho 50 ~+100 mm, botsitso ba ho kenya letsoho (24 h mocheso 2 ℃), mocheso o tlase oa mocheso o fetohang ka potlako oa mocheso o ka ntlafatsa haholo tlhahiso le ho fokotsa tšebeliso ea litšenyehelo.

·Tshebetso ea Ponahalo

Seipone se ka hare se bentšitsoe 'me se bentšitsoe ka ntle ho mat, ka ntle ho mahoashe Ra ≤ 0.8μm.

Karolo e ka Sehloohong

Sehlopha sena se nka sehlohloriso se ka holimo sa coaxial se boima ba 3, ho phahamisa le ho bula sekoahelo sa hydraulic, lebelo la homogenizing agitator e potlakileng: 0-3000r/min (taolo ea lebelo la ho sokoloha ha maqhubu), le lerako le korotlang butle, le its'oarellang ka tlase le leboteng. Vacuum suction ea amoheloa, haholo-holo bakeng sa lisebelisoa tsa phofo ho qoba ho fofa ha lerole. Tshebetso eohle e etsoa tlas'a maemo a vacuum ho thibela thepa hore e se ke ea hlahisa li-bubble tsa moea ka mor'a ho tsosoa ka lebelo le phahameng, tse ka finyellang litlhoko tsa bohloeki le bohloeki. Sistimi e na le sistimi ea tlhoekiso ea CIP, karolo ea ho ikopanya pakeng tsa setshelo le thepa e entsoe ka thepa ea SUS316L, 'me bokaholimo bo ka hare bo hloekisitsoe seipone (bohloeki).

Sehlopha sena se bonolo ho sebetsa, se tsitsitseng ts'ebetsong, se setle ka homogeneity, ts'ebetso e phahameng ea tlhahiso, e loketseng ho hloekisa, e utloahalang ka sebopeho, e nyenyane sebakeng sa fatše le e phahameng ka ho iketsetsa.